Back in October 2013, the Canadian government made a commitment to consult Canadians on how their food should be labelled. 3 years and 3 consultations later, a new and improved nutrition facts label has been presented.

When the new format becomes mandatory, manufacturers will be changing their labelling at a cost, of course. And, as transparency is now trending strongly in the food and beverage industry, manufacturers will also need to find ways to cope with other expected changes down the road.

Nutrition facts label still same shape, black and white

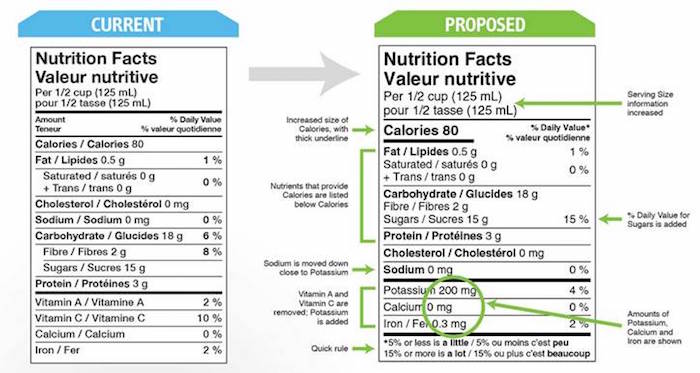

The new nutrition facts label is in the same simple rectangular shape and black and white scheme as the previous version. Colour coding had been discussed in the consultations but not retained.

Changes

Calories are more strongly identified and grouped with nutrients that make them up. There is also an important and long-overdue addition: The table now has the % daily value of sugars, recently established by the World Health Organization (WHO).

The ingredients list, a separate box, also has useful changes: ingredients are separated by bullets and thus easier to read. Also, the different sources of sugar are listed in parentheses, immediately after the word sugar. This certainly has educational value for the consumer, given the amount of places sugar can be found.

Changes not there, but to come

The consumer push for more transparency has recently made the labelling of Genetically Engineered foods mandatory across the USA. Even if the new law is perceived by some Americans as flawed and to be revised, There is a good chance that GMO labelling will eventually become mandatory in Canada too. This would represent more labelling changes and more costs for manufacturers.

Other additional changes could include more precise allergy information (although the new ingredients box does have a basic list at its bottom)

Manufacturer strategies

So, how can manufacturers continue to adapt to these changes?

There are strategies that enable more flexibility in label production, such as the use of inkjet printing technology. Black and white and colour inkjet printing costs have gone down considerably in the past few years and digital inkjet printing allows you easily make changes to your printed label image in a production run. This kind of adaptive technology is also ideal for short runs, with minimal set up costs.

Inkjet or flexo printing costs can be considerably lowered by bringing your label printing in-house. For this, costs and conditions should be looked at with a labelling and identification specialist.

A change in label could also be the opportunity for you to reconsider your branding. For example, going from self adhesive labels to shrink sleeve could allow you to incorporate the latest nutritional facts label information while taking advantage of vibrant, 360-degree colour branding to catch the customer’s eye.

Does your target customer react favorably to green initiatives? You could consider changing over to FSC approved labels or wash-off labels, that make recycling considerably easier.

There are many different strategies manufacturers can use to alleviate costs, or even be more profitable during mandatory label changes.

We’d be delighted to discuss them with you. Find out more!