In this post, we’ll explain HPP (high pressure processing). The use of High Pressure processing has been steadily growing in recent years. The current market is worth about $ 4 billion. In 2018 the market is expected to reach $ 12 billion according to Markets and Markets.

Although it’s results seem almost magical, it isn’t appropriate for all types of food packaging. We’ll talk about that later.

The process is particularly advantageous for cooked products, and healthy food. It is a perfect alternative to preservatives present in most food products.

Below, we’ll talk about how it works, and its benefits.

Finally, if you are interested by new packaging processes, read two of our previous articles:

- Compostable packaging made from mushrooms to replace plastic?

- Anamorphosis: a technical process applied to the manufacturing of sleeves

High Pressure Pasteurization: How it works

High pressure pasteurization involves treating food products at very high pressure. This pressure is equivalent to about 6000 bars, which corresponds to 6 times the pressure of the depths of the oceans.

Its force can change the structure of cells and cellular proteins and membranes.

Moreover, this process, unlike traditional ones, doesn’t require the addition of preservatives. It guarantees a preservation of the nutritional quality, vitamins and nutrients of food.

Fresh and safe food guaranteed!

HPP is also known as “pascalization”. It makes it possible to maintain a natural freshness of the product as well as its organoleptic qualities. Moreover, it’s a way of preserving the environment since there are no heat treatments and Chemical properties of the product.

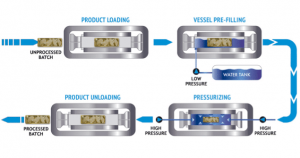

Here, is a diagram explaining the operation of a pasteurization machine:

How it works

Foods already in their packaging are inserted into a steel machine and are subjected to a very high level of pressure transmitted by water.

The pressure exerted on the food deactivates the bacterial flora of the product (bacteria, viruses, molds, etc.) and increases the shelf life and preservation.

Packaging capable of withstanding such treatment must:

- Be waterproof

- Have waterproof labels (otherwise, don’t include them in the process)

- Must include a surface capable of flexing up to 15%

- Be sealed tightly

- Include products that contain sufficient moisture to transmit pressure

- Contain as little air as possible

The main advantages of high pressure

Consumers want confidence in the products they buy. They demand a lot from packaging and many are willing to turn to brands offering alternatives to preservatives, chemicals, etc …

Among the main advantages of high pressure:

- Extended product lifetime

- Reduction of the bacterial flora of the products

- No use of preservatives and chemicals

- Can greatly extend shelf live of crustaceans and meat

- Machines use only water (no chemicals)

- Environmentally friendly process

The limits of the high-pressure processing

This method requires additional research and development to extend its application to all products. Indeed, HPP works well for products packaged in flexible packaging, but not for products that are dry or low in water.

Finally, even if the use of this process is a competitive advantage, high pressure machines are very expensive, so this is an important investment.

Did you like this post?

Do not hesitate to browse through our blog to learn more about packaging processes, labels and new technological to help your product stand out!